TT 1716

TT 1716 Specification

- Sealed

- Sealed Unit

- Surface Treatment

- Smooth Finish

- Thickness

- Standarad

- Cable Diameter

- 11 mm

- Product Type

- Terminal Block

- Material

- Plastic

- Application

- Industrial, Domestic

- Contact Resistance

- Below 5 m Ohms

- Insulation Resistance

- Above 100 M Ohms at 500 V DC

- Diameter

- 11 mm

- Terminal Socket

- Yes

- Style

- Round

- Fittings

- Plastic Molding Fittings

- Rated Voltage

- 220 Volt (V)

- Weight

- 35 gm

- Color

- White

- No. of Ways

- 16 Ways

- Connector Type

- Screw Type Terminal Block

- Operating Temperature Range

- -20°C to +60°C

- Flammability Rating

- UL94-V0

- Mounting Type

- Panel Mount

- Maximum Current

- 16 Amp

- Voltage Rating

- 220-250V

TT 1716 Trade Information

- Minimum Order Quantity

- 10000 Pieces

- Payment Terms

- Cash in Advance (CID), Cash Advance (CA)

- Supply Ability

- 10000 Pieces Per Week

- Delivery Time

- 4 Week

- Sample Available

- Yes

- Sample Policy

- Contact us for information regarding our sample policy

- Main Export Market(s)

- Western Europe, Australia, Middle East, Central America, Eastern Europe, Africa, South America, Asia, North America

- Main Domestic Market

- All India

About TT 1716

TT 1716

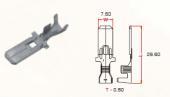

| CATEGORY NO | TAB SIZE | CABLE SIZE MM2 | DESCRIPTION | APPLICABLE MATING TERMINAL | MATERIAL | STANDARD PACKING QTY. [NOS.] |

| TT-1716 | 7.60 X 0.80 | 1.00- 2.50 | Folded male tab | TT-1727 | Brass | 2000 |

Reliable Electrical Connections

TT 1716 provides safe and efficient electrical connectivity with its screw type terminal block. Designed to handle up to 16 connection ways, it ensures stable distribution of electrical current in diverse applications, maintaining low contact resistance and excellent insulation properties for optimized performance.

Durable and Safe Construction

Fabricated from premium plastic with UL94-V0 flammability rating, the TT 1716 is engineered to resist fire and harsh conditions. The sealed, round style with smooth finish protects internal components, and its panel mount design offers secure and straightforward installation in both industrial and domestic settings.

Versatile Usage and Benefit

Supporting cable diameters up to 11 mm, TT 1716 is suitable for a variety of wiring requirements. Its high temperature tolerance, robust plastic molding fittings, and exceptional electrical characteristics make it an indispensable component for electrical infrastructure projects requiring reliability and safety.

FAQs of TT 1716:

Q: How is TT 1716 installed in an electrical panel?

A: TT 1716 is designed for panel mounting; it can be securely fitted into a panel using screws and plastic molding fittings. The installation process involves connecting wires to the screw type terminal blocks and ensuring all connections are tightened for safe operation.Q: What applications are suitable for TT 1716?

A: TT 1716 is ideal for both industrial and domestic electrical distribution systems due to its 16-way configuration, high current and voltage ratings, and reliable construction. It supports diverse environments needing stable, flame-retardant terminal blocks.Q: When should TT 1716 be used instead of other terminal blocks?

A: TT 1716 should be selected when projects require multiple connections (16 ways), high insulation resistance, low contact resistance, and UL94-V0 safety compliance, particularly in settings with stringent electrical safety and performance demands.Q: Where is TT 1716 manufactured and exported from?

A: TT 1716 is manufactured, supplied, and exported from India by industry specialists, ensuring quality control and adherence to international standards for electrical connectivity components.Q: What is the process for connecting cables to TT 1716?

A: To connect cables, ensure the panel is powered down, insert cables (up to 11 mm diameter) into the designated screw type terminals, tighten the screws, and check for secure fitting. The sealed plastic unit and terminal sockets provide clear guidance for proper insertion.Q: How does TT 1716 benefit electrical installations?

A: TT 1716 enhances electrical safety and system reliability with its robust insulation resistance, flame-retardant plastic, and smooth surface treatment. Its versatile design facilitates quick installation and maintenance, minimizing downtime and operational risks.

- Minimum Order Quantity

- 10000 Pieces

- Supply Ability

- 10000 Pieces Per Week

- Delivery Time

- 4 Week

- Main Domestic Market

- All India

- Main Export Market(s)

- Western Europe, Australia, Middle East, Central America, Eastern Europe, Africa, South America, Asia, North America

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in 312 Series Terminals Category

TT 1879

Minimum Order Quantity : 10000 Pieces

Product Type : Other, Terminal Connector

Color : Other, Silver

Weight : 22 Grams

Application : Electrical Cable Connection

Material : Other, Stainless Steel

TT 1755

Minimum Order Quantity : 10000 Pieces

Product Type : Other, Wire to Wire Connector

Color : Black

Weight : 30 Grams

Application : Automobile

Material : Other, Plastic & Brass

TT 1779

Minimum Order Quantity : 10000 Pieces

Product Type : Other, Electrical Socket

Color : White

Weight : 25 gm

Application : Electrical Fitting

Material : Polycarbonate

TT 1863

Minimum Order Quantity : 10000 Pieces

Product Type : Other, Test Terminal Block

Color : Black

Weight : 10 Grams

Application : Electrical/Electronic Panels

Material : Other, Phenolic Body, Brass Contacts

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free