TT 1818

TT 1818 Specification

- Surface Treatment

- Nickel Plated

- Thickness

- 5 Millimeter (mm)

- Sealed

- Yes

- Cable Diameter

- 4 mm-8 mm

- Product Type

- Industrial Plug

- Material

- Brass, Bakelite and Copper

- Application

- Electrical Connections

- Contact Resistance

- 5 Milliohm

- Insulation Resistance

- 1000 Megohms

- Diameter

- 18 mm

- Terminal Socket

- 4 Pin

- Style

- Round

- Fittings

- Brass

- Rated Voltage

- 220 Volt (V)

- Weight

- 180 Grams (g)

- Color

- Multi Color

- Operating Temperature Range

- -20°C to +70°C

- Mounting Type

- Panel Mount

- Connector Type

- Screw Terminal

- Protection Level

- IP65

- Current Rating

- 16 Ampere

TT 1818 Trade Information

- Minimum Order Quantity

- 10000 Pieces

- Payment Terms

- Cash in Advance (CID), Cash Advance (CA)

- Supply Ability

- 100000 Pieces Per Week

- Delivery Time

- 4 Months

- Sample Available

- Yes

- Sample Policy

- Contact us for information regarding our sample policy

- Main Export Market(s)

- Western Europe, Middle East, Eastern Europe, Africa, South America, Australia, Asia, Central America, North America

- Main Domestic Market

- All India

About TT 1818

TT 1818

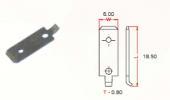

| CATEGORY NO | TAB SIZE | CABLE SIZE MM2 | DESCRIPTION | APPLICABLE MATING TERMINAL | MATERIAL | STANDARD PACKING QTY. [NOS.] |

| TT-1818 | 6.30X0.60 | 0.50-1.50 | Female with lancing | Blade fuse | Brass | 5000 |

Reliable Panel Mount Design

Engineered for straightforward panel installation, the TT 1818 connector features a screw terminal configuration and 4-pin socket, ensuring quick, secure electrical connections. Its round shape and compact dimensions make it compatible with various mounting requirements.

Exceptional Protection and Durability

With an IP65 rating and nickel-plated surface treatment, this connector endures harsh environments, protecting internal components from moisture and particulates. Built from brass, bakelite, and copper, it offers robustness and sustained performance across a wide temperature range.

FAQs of TT 1818:

Q: How do I properly install the TT 1818 connector on a panel?

A: The TT 1818 connector is designed for panel mounting. Secure the connector using the designated mounting holes, then connect your cables to the screw terminals, ensuring cable diameters between 4 mm and 8 mm fit snugly. Brass fittings and a 4-pin socket allow for reliable connections.Q: What benefits does the IP65 protection level provide for TT 1818 connectors?

A: An IP65 protection level means the TT 1818 connector is resistant to dust and protected against water jets, making it suitable for both indoor and outdoor electrical applications, and safeguarding your connections even in challenging conditions.Q: When should I consider using the TT 1818 connector for my electrical project?

A: Choose the TT 1818 connector for projects requiring secure, high-current (16A) connections, especially where environmental protection is crucial. Its wide operating temperature range and robust insulation make it ideal for industrial, commercial, and outdoor setups.Q: Where are TT 1818 connectors commonly utilized?

A: TT 1818 connectors are frequently used in industrial panels, machinery, and electrical equipment requiring dependable, sealed connections. Their panel mount design and resilience make them popular in manufacturing, automation, and exporting sectors.Q: What is the process to ensure optimal performance from the TT 1818 connector?

A: To maintain optimal performance, check that terminals are properly tightened and the connectors insulation resistance remains above 1000 Megohms. Periodically inspect the nickel-plated surface and connection integrity, especially in harsh environments.Q: How does using the TT 1818 connector benefit electrical systems?

A: The TT 1818 connector enhances reliability with low contact resistance (5 Milliohm), strong insulation, and durable construction. Its secure, sealed design minimizes risk of connection failure and prolongs system lifespan.

- Minimum Order Quantity

- 10000 Pieces

- Supply Ability

- 100000 Pieces Per Week

- Delivery Time

- 4 Months

- Main Domestic Market

- All India

- Main Export Market(s)

- Western Europe, Middle East, Eastern Europe, Africa, South America, Australia, Asia, Central America, North America

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in 250 Series Terminals Category

TT 1653

Minimum Order Quantity : 10000 Pieces

Color : Black

Product Type : Other, Terminal Block

Application : Electrical Wiring

Material : Nylon

Rated Voltage : 250 VAC

TT 1970

Minimum Order Quantity : 10000 Pieces

Color : Black

Product Type : Other, Terminal Block

Application : Electrical Panel

Material : Other, Bakelite

Rated Voltage : 220V 240V

TT 1972

Minimum Order Quantity : 10000 Pieces

Color : Black

Product Type : Other, Terminal Block

Application : Electrical Installations

Material : Other, Bakelite

Rated Voltage : 220 Volt (V)

TT 1982

Minimum Order Quantity : 10000 Pieces

Color : Black

Product Type : Other, Cable Gland Connector

Application : Industrial

Material : PVC

Rated Voltage : 250V

Send Inquiry

Send Inquiry Send SMS

Send SMS