TT 1812

TT 1812 Specification

- Sealed

- NO

- Cable Diameter

- 6 - 10 mm

- Thickness

- Standard

- Surface Treatment

- Glossy

- Product Type

- Round Mains Connector

- Material

- Polycarbonate

- Application

- Suitable for connecting main cables

- Contact Resistance

- 0.01

- Insulation Resistance

- 1000M at 500V DC

- Diameter

- 18 mm

- Terminal Socket

- 2 Pin

- Style

- Inline

- Fittings

- Brass

- Rated Voltage

- 250V

- Weight

- 22g

- Color

- White

- Ingress Protection

- IP20

- Mounting

- Cable Mount

- Standards Compliance

- IS 1293

- Current Rating

- 6 A

- Temperature Range

- -20°C to +70°C

- Locking

- Screw Type

- Flame Retardant

- Yes

TT 1812 Trade Information

- Minimum Order Quantity

- 10000 Pieces

- Payment Terms

- Cash in Advance (CID), Cash Advance (CA)

- Supply Ability

- 100000 Pieces Per Month

- Delivery Time

- 4 Week

- Sample Available

- Yes

- Sample Policy

- Contact us for information regarding our sample policy

- Main Export Market(s)

- Western Europe, Australia, Middle East, Central America, Africa, South America, Asia, Eastern Europe, North America

- Main Domestic Market

- All India

About TT 1812

TT 1812

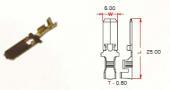

| CATEGORY NO | TAB SIZE | CABLE SIZE MM2 | DESCRIPTION | APPLICABLE MATING TERMINAL | MATERIAL | STANDARD PACKING QTY. [NOS.] |

| TT-1812 | 6.30 X 0.80 | 0.50- 1.00 | Female with Dimple & Window close Barrel | TT-1969 | Brass | 5000 |

| Remarks Loose |

Reliable and Durable Construction

The TT 1812 is built from high-quality polycarbonate, ensuring strength while maintaining a lightweight profile. Its brass fittings, standard thickness, and glossy surface treatment provide durability and aesthetic appeal. The screw-type locking mechanism secures cable connections, reducing the risk of accidental disconnection. This inline terminal socket is tailored for rigorous applications in industrial and commercial settings.

Standards-Compliant and Safe Operation

Meeting IS 1293 standards and featuring flame-retardant properties, the TT 1812 is engineered for safety and regulatory compliance. With insulation resistance of 1000M at 500V DC and contact resistance 0.01, it minimizes electrical hazards. Its IP20 ingress protection safeguards against dust and accidental contact, making it a dependable component for main cable interconnections.

FAQs of TT 1812:

Q: How do I install the TT 1812 terminal socket?

A: To install the TT 1812, insert the main cable (with an outer diameter of 6 to 10 mm) into the terminal socket, secure the wires in place using the screw-type locking mechanism, and ensure tight fittings for stable connectivity. No additional sealing is required as the unit is not sealed.Q: What applications is the TT 1812 suitable for?

A: The TT 1812 is designed for connecting main cables in electrical installations, particularly where a two-pin inline cable mount socket is needed. Its construction and compliance with IS 1293 make it suitable for both industrial and domestic use.Q: When should I consider using the TT 1812 socket?

A: You should use the TT 1812 when you require a reliable, flame-retardant main cable connector that can operate between -20C and +70C, provides IP20 ingress protection, and meets Indian safety standards.Q: Where can the TT 1812 be installed?

A: This socket can be installed in locations that are dry and protected from direct water exposure (as it is rated IP20), such as junction boxes, control panels, or internal wiring cabinets.Q: What are the benefits of using a polycarbonate body and glossy finish?

A: A polycarbonate body ensures impact resistance and durability, while the glossy finish provides an attractive appearance and facilitates easy cleaning, ensuring the socket maintains both function and form over time.Q: How does the TT 1812 ensure reliable electrical connections?

A: Its brass fittings, high insulation resistance (1000M at 500V DC), and low contact resistance (0.01) contribute to minimal power loss, reduced heating, and consistent performance.Q: What process should be followed to maintain the TT 1812?

A: Periodic inspection is recommended to check for dust build-up or loose connections; clean the socket with a dry cloth and ensure all screws are firmly tightened for optimal operation.

- Minimum Order Quantity

- 10000 Pieces

- Supply Ability

- 100000 Pieces Per Month

- Delivery Time

- 4 Week

- Main Domestic Market

- All India

- Main Export Market(s)

- Western Europe, Australia, Middle East, Central America, Africa, South America, Asia, Eastern Europe, North America

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in 250 Series Terminals Category

TT 2012

Minimum Order Quantity : 10000 Pieces

Cable Diameter : 6 mm

Sealed : Yes

Style : Modern

Product Type : Other, Terminal Block

Application : Electrical Wiring

TT 1925

Minimum Order Quantity : 10000 Pieces

Cable Diameter : 6 mm

Sealed : Other, Unsealed

Style : Screw Type

Product Type : Other, Pin Type Terminal

Application : Electrical Connection

TT 1824

Minimum Order Quantity : 10000 Pieces

Cable Diameter : 18 mm x 24 mm

Sealed : Yes

Style : Standard

Product Type : Other, Electrical Junction Box

Application : Industrial, Commercial and Household Electrical Connection

TT 2972

Minimum Order Quantity : 10000 Pieces

Cable Diameter : 6 mm

Sealed : Yes

Style : Straight

Product Type : Other, 3 Pin Top Plug

Application : Electrical Power Distribution

Send Inquiry

Send Inquiry Send SMS

Send SMS