TT 1925

TT 1925 Specification

- Thickness

- 1.5 mm

- Sealed

- Unsealed

- Surface Treatment

- Polished

- Cable Diameter

- 6 mm

- Product Type

- Pin Type Terminal

- Material

- Phenolic

- Application

- Electrical Connection

- Contact Resistance

- 0.01

- Insulation Resistance

- 100 M at 500V DC

- Diameter

- 12 mm

- Terminal Socket

- Brass Socket

- Style

- Screw Type

- Fittings

- Brass Terminals

- Rated Voltage

- 250 V AC

- Weight

- 8 Grams

- Color

- Black

- Flame Retardant

- Yes

- Length

- 25 mm

- Current Rating

- 10 Amp

- Mounting Type

- Panel Mount

- Working Temperature

- -20°C to +80°C

- Number of Terminals

- 2

- Mechanical Endurance

- > 500 Cycles

TT 1925 Trade Information

- Minimum Order Quantity

- 10000 Pieces

- Payment Terms

- Cash Advance (CA), Cash in Advance (CID)

- Supply Ability

- 100000 Pieces Per Week

- Delivery Time

- 4 Week

- Sample Available

- Yes

- Sample Policy

- Contact us for information regarding our sample policy

- Main Export Market(s)

- Western Europe, Australia, Middle East, Central America, Eastern Europe, South America, Asia, North America

- Main Domestic Market

- All India

About TT 1925

TT 1925

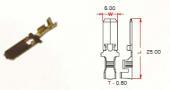

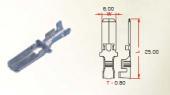

| CATEGORY NO | TAB SIZE | CABLE SIZE MM2 | DESCRIPTION | APPLICABLE MATING TERMINAL | MATERIAL | STANDARD PACKING QTY. [NOS.] |

| TT-1925 | 6.30 X 0.80 | 0.50- 1.00 | Folded male tab | TT-1909 | Brass | 6000 |

Engineered for Safety and Durability

Crafted from phenolic material and equipped with flame retardant properties, the TT 1925 ensures operational safety under rigorous conditions. Its high insulation resistance of 100 M at 500V DC and reliable contact resistance make it a dependable choice for critical electrical applications.

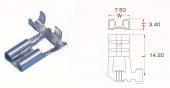

Flexible Installation with Brass Screw Terminals

The TT 1925 features screw-type brass terminals and sockets, designed for secure and easy panel mounting. Suitable for cables up to 6 mm in diameter, its simple yet robust fittings streamline the installation process and maintain strong electrical conductivity.

Versatile Use Across Electrical Connections

Thanks to its wide operating temperature range, mechanical endurance of over 500 cycles, and compact profile (25 mm length, 12 mm diameter), the TT 1925 serves diverse industrial and commercial electrical needs. Its polished finish and high-quality construction ensure consistent, long-term performance.

FAQs of TT 1925:

Q: How do I install the TT 1925 panel mount connector?

A: Installation is straightforward: mount the connector on your panel using the provided screw-type fittings. Connect the wiring to the two brass terminals, which accommodate cable diameters up to 6 mm, and secure the connections for a stable electrical fit.Q: What are the key benefits of choosing the TT 1925 for electrical connections?

A: The TT 1925 stands out for its flame retardant phenolic body, high insulation (100 M), excellent contact resistance ( 0.01 ), and robust mechanical endurance (> 500 cycles). These features collectively enhance safety, durability, and electrical reliability.Q: Where can the TT 1925 connector be used?

A: This connector is ideal for both industrial and commercial electrical setups requiring reliable panel-mounted connections. Its wide operating temperature range and flame retardant construction make it suitable for environments that demand high safety standards.Q: What is the process for wiring the TT 1925 connector?

A: Begin by stripping the cable end (up to 6 mm diameter), insert it into the brass terminal socket, and tighten the screw for a firm connection. Ensure the wiring is secure and there is no exposed conductor before completing the panel mount.Q: When should I consider replacing the TT 1925 connector?

A: Though engineered for over 500 mechanical cycles, replacement is recommended if physical damage, excessive wear, or degradation in electrical performance (such as unusual resistance changes) occurs. Regular inspection will help maintain optimal safety and reliability.Q: What safety standards does the TT 1925 adhere to?

A: The connector is designed with flame retardant phenolic material, provides high insulation resistance, and uses polished brass components for secure conductivity, aligning with key safety requirements for electrical components.Q: Who manufactures and supplies the TT 1925 connector?

A: The TT 1925 is manufactured, supplied, and exported by leading electrical component manufacturers based in India, ensuring global availability and support for diverse customer needs.

- Minimum Order Quantity

- 10000 Pieces

- Supply Ability

- 100000 Pieces Per Week

- Delivery Time

- 4 Week

- Main Domestic Market

- All India

- Main Export Market(s)

- Western Europe, Australia, Middle East, Central America, Eastern Europe, South America, Asia, North America

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in 250 Series Terminals Category

TT 2996

Minimum Order Quantity : 10000 Pieces

Material : Aluminum

Color : Other, Silver

Application : Electrical Fitting

Product Type : Other, Flexible Conduit Gland

Rated Voltage : 220250 V

TT 1810K

Minimum Order Quantity : 10000 Pieces

Material : Other, Bakelite

Color : Black

Application : Panel Wiring

Product Type : Other, Terminal Block

Rated Voltage : 250V AC

TT 2011

Minimum Order Quantity : 10000 Pieces

Material : Other, Stainless Steel

Color : Other, Silver & Black

Application : Industrial

Product Type : Other, Thermowell

Rated Voltage : 220380 Volt (V)

TT 1866

Minimum Order Quantity : 10000 Pieces

Material : Other, Thermoplastic

Color : White

Application : Electrical Connections

Product Type : Other, Terminal Block

Rated Voltage : 250 Volts

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free