TT 1011

TT 1011 Specification

- Application

- Automotive, Machinery, Home Appliances

- Product Type

- Terminal

- Material

- Other

- Weight

- 50-100 Grams (g)

- Color

- Golden

TT 1011 Trade Information

- Minimum Order Quantity

- 10000 Pieces

- Payment Terms

- Cash in Advance (CID), Cash Advance (CA)

- Supply Ability

- 100000 Pieces Per Week

- Delivery Time

- 4 Week

- Sample Available

- Yes

- Sample Policy

- Contact us for information regarding our sample policy

- Main Export Market(s)

- Western Europe, Eastern Europe, Central America, Africa, Middle East, South America, Asia, North America, Australia

- Main Domestic Market

- All India

About TT 1011

TT 1011

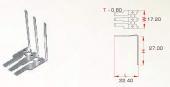

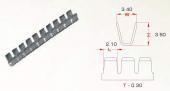

| CATEGORY NO | TAB SIZE | CABLE SIZE MM2 | DESCRIPTION | APPLICABLE MATING TERMINAL | MATERIAL | STANDARD PACKING QTY. [NOS.] |

| TT-1011 | 6.30 x 0.80 | 2.00- 4.00 | Female with dimple & window | TT-1969 | Brass | 4000 |

Reliable Multi-Industry Component

TT 1011 is engineered to meet the demanding standards of automotive, machinery, and home appliance sectors. Its golden finish enhances corrosion resistance and adds aesthetic value. Available in weights ranging from 50 to 100 grams, this component is both versatile and robust, ensuring seamless integration in diverse equipment.

Expert Manufacturing and Supply from India

As a premier manufacturer, exporter, and supplier based in India, we prioritize quality and precision in every TT 1011 piece. Our advanced production processes guarantee consistent results, and our strong logistics network enables efficient distribution across global markets.

FAQs of TT 1011:

Q: How is TT 1011 applied in automotive, machinery, and home appliances?

A: TT 1011 serves as a critical component in assembling and enhancing the functionality of vehicles, industrial machines, and various home appliances due to its reliability and suitable weight range.Q: What materials are used in the manufacturing of TT 1011?

A: TT 1011 is produced using robust materials that ensure durability and strength, complemented by a golden coating for improved corrosion resistance and visual appeal.Q: When should TT 1011 be replaced or maintained?

A: Regular inspection is recommended for TT 1011 during scheduled equipment maintenance. Replacement may be advised if wear, deformation, or corrosion is detected to ensure peak performance.Q: Where can TT 1011 be sourced from?

A: TT 1011 is manufactured, supplied, and exported from India by reputable companies specializing in industrial components. It is readily available for international and domestic procurement.Q: What is the manufacturing process for TT 1011?

A: TT 1011 is produced through precision machining and finishing processes under strict quality control standards, resulting in consistent weight, accuracy, and durability.Q: How should TT 1011 be used for optimal benefit?

A: For best results, incorporate TT 1011 according to equipment specifications and industry standards, ensuring proper installation to maximize performance and lifespan.Q: What are the main benefits of choosing TT 1011?

A: TT 1011 offers high strength, reliable operation, corrosion resistance, and flexibility for use across various sectors, making it a valuable choice for manufacturers and end-users alike.

- Minimum Order Quantity

- 10000 Pieces

- Supply Ability

- 100000 Pieces Per Week

- Delivery Time

- 4 Week

- Main Domestic Market

- All India

- Main Export Market(s)

- Western Europe, Eastern Europe, Central America, Africa, Middle East, South America, Asia, North America, Australia

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Terminals Category

TT 1656

Minimum Order Quantity : 10000 Pieces

Material : Plastic and Metal , Other

Weight : 50100 Grams (g)

Color : Silver , Other

Product Type : Other, Terminal

Application : Automotive, Machinery, Home Appliances

Copper Ring Terminals

Minimum Order Quantity : 10000 Pieces

Material : Other, Plastic and Metal

Weight : 50100 Grams (g)

Color : Other, Silver

Product Type : Terminals, Other

Application : Automotive, Machinery, Home Appliances

Ring Terminals

Minimum Order Quantity : 10000 Pieces

Material : Other

Weight : 50100 Grams (g)

Color : Other, Silver and Golden

Product Type : Other

Application : Automotive, Home Appliances, Machinery

TT 1938

Minimum Order Quantity : 10000 Pieces

Material : Other, Plastic and Metal

Weight : 50100 Grams (g)

Color : Other, Silver

Product Type : Other, Terminal

Application : Automotive, Machinery, Home Appliances

Send Inquiry

Send Inquiry Send SMS

Send SMS